Your How to avoid air bubbles in concrete images are available in this site. How to avoid air bubbles in concrete are a topic that is being searched for and liked by netizens today. You can Download the How to avoid air bubbles in concrete files here. Download all free images.

If you’re looking for how to avoid air bubbles in concrete images information related to the how to avoid air bubbles in concrete keyword, you have come to the ideal blog. Our website frequently gives you suggestions for viewing the maximum quality video and picture content, please kindly hunt and find more informative video articles and graphics that match your interests.

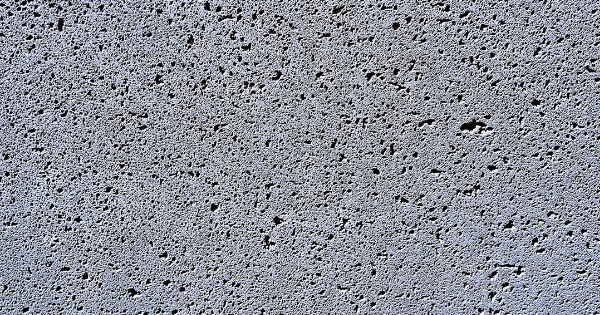

How To Avoid Air Bubbles In Concrete. Creating a well-ventilated work area while taking care to prevent unnecessary or forceful air flow can prevent bubbles from forming in the coating. When the aggregate is more uniform the concrete will become more fluid so the chance that water and air can get trapped decreases. Let them sit for 5 mins then go back to them gently tap the sides and tghis will release further air. If required by specifications extreme caution should be exercised when timing the finishing operation.

How To Prevent Air Bubbles When Casting Concrete Statuary Youtube From youtube.com

How To Prevent Air Bubbles When Casting Concrete Statuary Youtube From youtube.com

Cover with plastic sheeting and wait for it to harden. Allow this solution to sit on the concrete for up to two minutes. Changes to the concrete mix design maybe required to ensure the correct viscosity for the application. Excessive air movement from open doorways HVAC units fans or the like can agitate the coating as it cures causing bubbles to form. Pour your cement in layers. Protect surface from premature drying and evaporation.

Especially if the stone is for an exterior application.

There are a variety of reduction agents that are added to concrete during the mixing stages to help reduce air bubbles from forming. Make sure your concrete mix is not too thick. Look for any recommended local brand of reducing agent to add to the concrete and reduce the possibility of bubbles forming. It does work though. In order to get air bubbles out of your concrete floor coatings you can roughen up the coating with 60 grit screen. Hammering the mold can eliminate any residual voids.

Source: graco.com

Source: graco.com

Pour your cement in layers. Protect surface from premature drying and evaporation. Let them sit for 5 mins then go back to them gently tap the sides and tghis will release further air. Why is there air in my concrete mix. Every concrete floor is different and the porosity of the concrete plays a major part in causing air bubbles and blisters.

Source: precast.org

Source: precast.org

Cover with plastic sheeting and wait for it to harden. When the aggregate is more uniform the concrete will become more fluid so the chance that water and air can get trapped decreases. To reduce the impact treating the concrete with an epoxy primersealer is important. If you havent got a vibrating table to put your moulds on massage and flex the moulds so the concrete runs into the fine detail. Traps smaller and more uniform air bubbles than the air trapped as the c o n c r ete is placed into the forms.

Source: blog.ecoratio.com

Source: blog.ecoratio.com

This is called air entrainment. Excessive air movement from open doorways HVAC units fans or the like can agitate the coating as it cures causing bubbles to form. - Yes having a certain amount of air in your mix is actually desirable. Every concrete floor is different and the porosity of the concrete plays a major part in causing air bubbles and blisters. Changes to the concrete mix design maybe required to ensure the correct viscosity for the application.

Source: youtube.com

Source: youtube.com

Youll want to make sure you are using the recommended roller type too to prevent air bubbles during the application process. Cover with plastic sheeting and wait for it to harden. If the concrete flooring is new let it cure for at least 28 days before applying a sealer. Especially if the stone is for an exterior application. Do not use a jitterbug or excessive vibration such as a vibratory screed on slumps over 5 inches 125 mm.

Source: researchgate.net

Source: researchgate.net

Air flow across the coating. Why is there air in my concrete mix. These bubbles result in weak spots that arent able to handle pressure. When the aggregate is more uniform the concrete will become more fluid so the chance that water and air can get trapped decreases. This is called air entrainment.

Source: creare.com

Source: creare.com

Vibrating both the outside and inside of your mold will draw most air and water bubbles away from the surface of the concrete. Surface voids as pinholes and air bubbles are caused when air is entrapped during the curing of the concrete. If the concrete is extremely porous then a second coat of primersealer should be applied. Look for any recommended local brand of reducing agent to add to the concrete and reduce the possibility of bubbles forming. Surface voids as pinholes and air bubbles are caused when air is entrapped during the curing of the concrete.

Source: nevadareadymix.com

Source: nevadareadymix.com

The type of productmouldcompaction will have a direct impact on the mix viscosity required. Dampen the concrete with a solution of one part hydrochloric acid and four parts water. To reduce the impact treating the concrete with an epoxy primersealer is important. For example if the tip. Hammering the mold can eliminate any residual voids.

Source: blog.ecoratio.com

Source: blog.ecoratio.com

The type of productmouldcompaction will have a direct impact on the mix viscosity required. - Yes having a certain amount of air in your mix is actually desirable. Techniques used during vibration can eliminate most surface voids. Air flow across the coating. In order to get air bubbles out of your concrete floor coatings you can roughen up the coating with 60 grit screen.

Source: slabjackgeotechnical.com

Source: slabjackgeotechnical.com

Changes to the concrete mix design maybe required to ensure the correct viscosity for the application. Do not use a jitterbug or excessive vibration such as a vibratory screed on slumps over 5 inches 125 mm. Changes to the concrete mix design maybe required to ensure the correct viscosity for the application. This will allow the air to escape and take down the texture of the bubbles. Surface voids as pinholes and air bubbles are caused when air is entrapped during the curing of the concrete.

Source: concretecountertopinstitute.com

Source: concretecountertopinstitute.com

Air flow across the coating. More vibration is necessary with impermeable forms to move the air voids to the free surface of the concrete. Traps smaller and more uniform air bubbles than the air trapped as the c o n c r ete is placed into the forms. These bubbles result in weak spots that arent able to handle pressure. Dampen the concrete with a solution of one part hydrochloric acid and four parts water.

Source: concreteconstruction.net

Source: concreteconstruction.net

How to Get Air Bubbles Out of Cement. Every concrete floor is different and the porosity of the concrete plays a major part in causing air bubbles and blisters. Concrete is a mixture of gravel sand and cement among other ingredients and when this mix gets poured into forms or molds trapped air bubbles can form. Changes to the concrete mix design maybe required to ensure the correct viscosity for the application. Youll want to make sure you are using the recommended roller type too to prevent air bubbles during the application process.

Source: theconstructor.org

Source: theconstructor.org

Allow this solution to sit on the concrete for up to two minutes. Lime calcium chloride and plasticizes are the most commonly used reduction agents to reduce air bubbles in the cement mixture. Make sure your concrete mix is not too thick. Do not use a jitterbug or excessive vibration such as a vibratory screed on slumps over 5 inches 125 mm. Every concrete floor is different and the porosity of the concrete plays a major part in causing air bubbles and blisters.

Source: youtube.com

Source: youtube.com

Bubbles should no longer be forming before you rinse it off completely. Dampen the concrete with a solution of one part hydrochloric acid and four parts water. Tip 4 Use aggregate that does not have irregular pieces in your concrete mix. The amount of air incorporated by mixing depends on the fluidity of the concre t e and on the mechanics of the mixing and tumbling action. Changes to the concrete mix design maybe required to ensure the correct viscosity for the application.

Source: forconstructionpros.com

Source: forconstructionpros.com

Let them sit for 5 mins then go back to them gently tap the sides and tghis will release further air. Each layer should be slightly thinner than the length of the tip on the concrete vibrator. The type of productmouldcompaction will have a direct impact on the mix viscosity required. Protect surface from premature drying and evaporation. The trick is to c r eate and retain bubbles of the right.

Source: learncoatings.com

Source: learncoatings.com

This is called air entrainment. Excessive air movement from open doorways HVAC units fans or the like can agitate the coating as it cures causing bubbles to form. Look for any recommended local brand of reducing agent to add to the concrete and reduce the possibility of bubbles forming. For example if the tip. Each layer should be slightly thinner than the length of the tip on the concrete vibrator.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to avoid air bubbles in concrete by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.