Your Concrete slab sub base material images are available in this site. Concrete slab sub base material are a topic that is being searched for and liked by netizens today. You can Get the Concrete slab sub base material files here. Find and Download all free images.

If you’re searching for concrete slab sub base material pictures information connected with to the concrete slab sub base material interest, you have pay a visit to the ideal blog. Our site frequently gives you hints for downloading the maximum quality video and image content, please kindly hunt and find more informative video articles and images that fit your interests.

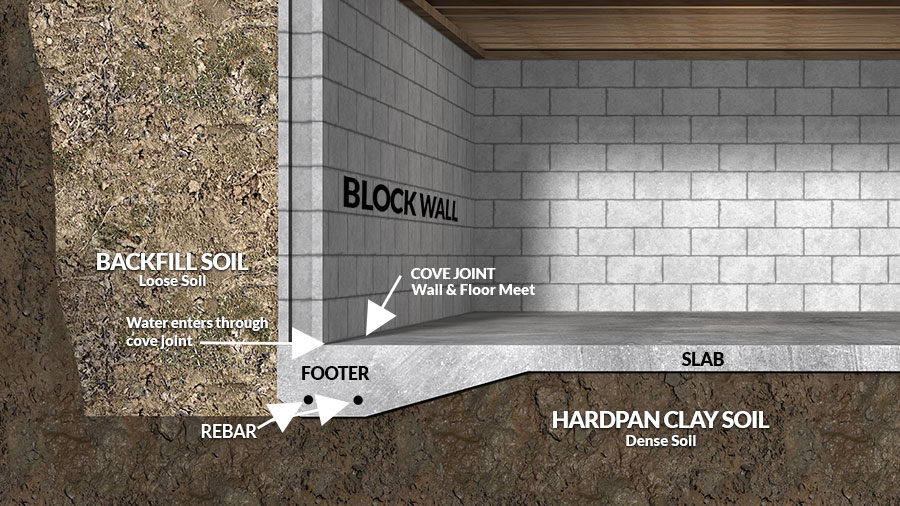

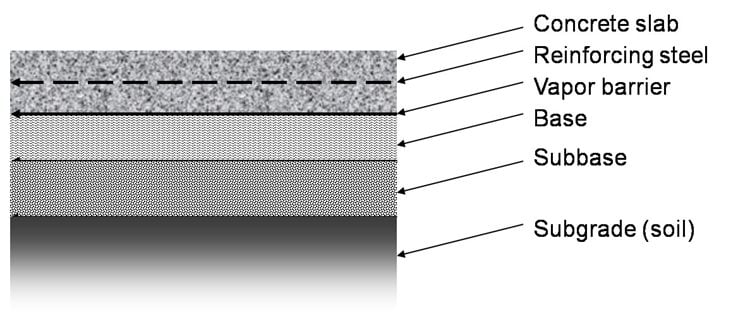

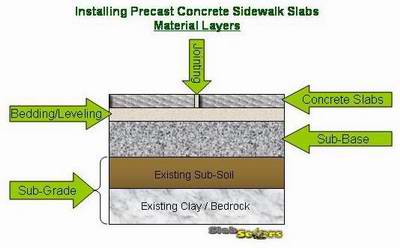

Concrete Slab Sub Base Material. This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement. A subgrade is made up of native soil that has been compacted to withstand the loads above it. RCA subbase condition underneath concrete slab after coring 11. The base course material according to ACI 302 Concrete Floor and Slab Construction should be compactible easy to trim granular fill that will remain stable and support construction traffic ACI 302 recommends material with 10 to 30 fines passing the No.

Subgrade And Subbase For Concrete Slab Constro Facilitator From constrofacilitator.com

Subgrade And Subbase For Concrete Slab Constro Facilitator From constrofacilitator.com

Granular material is laid over the soil or subsoil and compacted to create the right conditions for putting down such surface materials as paving blocks asphalt or concrete. They are both crushed stone. I It aids in reducing the frictional forces between concrete slab and sub-base and helps to movement of concrete slab with respect to sub-base owing to changes in temperature and moisture. Cooperative surveys by state agencies covered more than 2000 miles of concrete pavements in ten states. Sub-grade support can be considerably improved by installing a cement-treated sub-base soil cement controlled low-strength material CLSM or lean concrete sub-base. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged.

Granular material is laid over the soil or subsoil and compacted to create the right conditions for putting down such surface materials as paving blocks asphalt or concrete.

Sub-grade support can be considerably improved by installing a cement-treated sub-base soil cement controlled low-strength material CLSM or lean concrete sub-base. Geotechnical engineers typically are contracted by owners to evaluate soil conditions on a construction site and sometimes they specify the subbase fill materials to be used and how they should be placed. For bitumen-bound material then 50mm is a typical minimum thickness. The subbase is literally the foundation and with it you dont have to worry about the subgrade material. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. Cooperative surveys by state agencies covered more than 2000 miles of concrete pavements in ten states.

Source: specifyconcrete.org

Source: specifyconcrete.org

Outline Background Material. RCA subbase condition underneath concrete slab after coring 11. The subbase placement is optional and it serves as a work platform for construction of the slab and provide more uniform support for the slab. 2211 Base course and sub-base materials will be of a type approved by the Contract Administrator. They are both crushed stone.

Source: constrofacilitator.com

Source: constrofacilitator.com

Granular material is laid over the soil or subsoil and compacted to create the right conditions for putting down such surface materials as paving blocks asphalt or concrete. RCA subbase condition underneath concrete slab after coring 11. Type 1 has a maximum permitted top size of 63mm graded down to dust. The rigid pavement has a slab action and is capable of transmitting the wheel load stresses through a wider area below. The sub-base material should be spread out in layers no thicker than 150mm and roughly levelled with spades rakes or similar.

Source: researchgate.net

Source: researchgate.net

Cooperative surveys by state agencies covered more than 2000 miles of concrete pavements in ten states. These represented a wide range of climates soils traffic conditions and pavements with and. I It aids in reducing the frictional forces between concrete slab and sub-base and helps to movement of concrete slab with respect to sub-base owing to changes in temperature and moisture. The rigid pavement has a slab action and is capable of transmitting the wheel load stresses through a wider area below. 2211 Base course and sub-base materials will be of a type approved by the Contract Administrator.

Source: slabsetters.com

Source: slabsetters.com

Concrete slabs were placed directly on top of the subgrade without any basesubbase layers. It can be clay soil dirt none of it will matter when you have a proper layer under the concrete. Generally cement treated and lean concrete sub-bases are 4 to 6 inches thick. The subbase according to ACI 3021 Guide to Concrete Floor and Slab Construction is a layer on top of the subgrade of compactible easy to trim granular fill that will remain stable and support construction traffic In some. Adequately designed and properly constructed unstabilized bases exhibit excellent field performance at a lower cost than stabilized bases.

Source: concretenetwork.com

Source: concretenetwork.com

The rigid pavement slab as tensile strength tensile stresses are developed due to the bending of the slab under the wheel load temperature variations Providing a good base. Generally a flexible sub-base of unbound material needs to be at least 100mm deep as does a bound sub-base of CBMHBM. Army Corps of Engineers led to a much better understanding of the importance of the use of bases and subbases their uniformity and degree of compaction. Weak subgrade and subbase layers can settle differently across the surface and cause cracks in the concrete. Cooperative surveys by state agencies covered more than 2000 miles of concrete pavements in ten states.

Source: concretenetwork.com

Source: concretenetwork.com

Any concrete project needs at least a compacted soil subgrade layer. This pivotal work on rigid pavement design by the US. Cooperative surveys by state agencies covered more than 2000 miles of concrete pavements in ten states. Granular material is laid over the soil or subsoil and compacted to create the right conditions for putting down such surface materials as paving blocks asphalt or concrete. BaseSubbase Material Characteristics Unstabilized bases also frequently referred to as granular bases are the most commonly used base types for concrete pavements.

Source: podovigrupa.com

Source: podovigrupa.com

The sub-base material should be spread out in layers no thicker than 150mm and roughly levelled with spades rakes or similar. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged. 2211 Base course and sub-base materials will be of a type approved by the Contract Administrator. For bitumen-bound material then 50mm is a typical minimum thickness. 2213 Base course and sub-base materials shall conform to the grading requirements in.

Source: yanpage.narod.ru

Source: yanpage.narod.ru

The rigid pavement slab as tensile strength tensile stresses are developed due to the bending of the slab under the wheel load temperature variations Providing a good base. This pivotal work on rigid pavement design by the US. The subbase placement is optional and it serves as a work platform for construction of the slab and provide more uniform support for the slab. It is caused by frequent slab deflections under heavy wheel loads and eventually leads to the displacement of enough soil so that slab edges and corners are left unsupported. The rigid pavement has a slab action and is capable of transmitting the wheel load stresses through a wider area below.

Source: concretenetwork.com

Source: concretenetwork.com

A concrete surface is only as stable and level as its subgrade and subbase. Weak subgrade and subbase layers can settle differently across the surface and cause cracks in the concrete. Generally a flexible sub-base of unbound material needs to be at least 100mm deep as does a bound sub-base of CBMHBM. The sub-base material should be spread out in layers no thicker than 150mm and roughly levelled with spades rakes or similar. 2213 Base course and sub-base materials shall conform to the grading requirements in.

Source: pinterest.com

Source: pinterest.com

Adequately designed and properly constructed unstabilized bases exhibit excellent field performance at a lower cost than stabilized bases. 100 sieve with no clay silt or organic materials. RCA subbase condition underneath concrete slab after coring 11. The subbase according to ACI 3021 Guide to Concrete Floor and Slab Construction is a layer on top of the subgrade of compactible easy to trim granular fill that will remain stable and support construction traffic In some. This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement.

Source: concretenetwork.com

Source: concretenetwork.com

Adequately designed and properly constructed unstabilized bases exhibit excellent field performance at a lower cost than stabilized bases. I It aids in reducing the frictional forces between concrete slab and sub-base and helps to movement of concrete slab with respect to sub-base owing to changes in temperature and moisture. The base course material according to ACI 302 Concrete Floor and Slab Construction should be compactible easy to trim granular fill that will remain stable and support construction traffic ACI 302 recommends material with 10 to 30 fines passing the No. A concrete surface is only as stable and level as its subgrade and subbase. Having a gravel layer helps keep the slabs even prevents cracks helps with water drains and helps avoid low spots within the subgrade.

Source: concretenetwork.com

Source: concretenetwork.com

2212 Base course and sub-base materials shall be sound durable particles produced by crushing screening and grading of recovered materials. A thick gravel subbase and base may also be required and are usually worth the effort. These represented a wide range of climates soils traffic conditions and pavements with and. Theres a rule of thumb that we use with fill layers - they should always be at least twice the thickness of the largest particle size. The rigid pavement slab as tensile strength tensile stresses are developed due to the bending of the slab under the wheel load temperature variations Providing a good base.

Source: tristar-concrete.com

Source: tristar-concrete.com

This is done by laying down a sub-base a layer of aggregate material that is placed above the subgrade to prevent soil displacement. The subbase is the finely graded compactable material between the subgrade and the concrete. The subbase according to ACI 3021 Guide to Concrete Floor and Slab Construction is a layer on top of the subgrade of compactible easy to trim granular fill that will remain stable and support construction traffic In some. The most common granular aggregate sub-base is DoT Department of Transport Type 1 and Type 3 Limestone. 2211 Base course and sub-base materials will be of a type approved by the Contract Administrator.

Source: slabsetters.com

Source: slabsetters.com

A subgrade is made up of native soil that has been compacted to withstand the loads above it. A thick gravel subbase and base may also be required and are usually worth the effort. 2213 Base course and sub-base materials shall conform to the grading requirements in. Outline Background Material. Generally cement treated and lean concrete sub-bases are 4 to 6 inches thick.

Source: pavingexpert.com

Source: pavingexpert.com

Granular material is laid over the soil or subsoil and compacted to create the right conditions for putting down such surface materials as paving blocks asphalt or concrete. Adequately designed and properly constructed unstabilized bases exhibit excellent field performance at a lower cost than stabilized bases. In concrete pavement terminology the subgrade the native soil on which the pavement is built must be protected and compacted to ensure it stays in its place and isnt damaged. This pivotal work on rigid pavement design by the US. The rigid pavement slab as tensile strength tensile stresses are developed due to the bending of the slab under the wheel load temperature variations Providing a good base.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title concrete slab sub base material by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.