Your Concrete slab casting procedure images are available. Concrete slab casting procedure are a topic that is being searched for and liked by netizens now. You can Download the Concrete slab casting procedure files here. Find and Download all free vectors.

If you’re looking for concrete slab casting procedure pictures information related to the concrete slab casting procedure topic, you have pay a visit to the ideal blog. Our site always provides you with hints for seeing the maximum quality video and image content, please kindly hunt and locate more enlightening video articles and graphics that fit your interests.

Concrete Slab Casting Procedure. A guide to the correct number and po-. Marking the slab. Simple residential basement slab to a heavy-duty industrial floor. Concrete Slab Step-by-Step.

Method Statement For Pouring Concrete On Slab On Grade From qualityengineersguide.com

Method Statement For Pouring Concrete On Slab On Grade From qualityengineersguide.com

Laitance removal and slurry chipping on slab at column top. The first step is to bring together and put up formwork the second step is to put in order and place reinforcement the third step is. After filling and rodding raise the cone to allow the concrete to subside. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab. Columns will be first cast below the proposed beam bottom levels using concrete of the mix as per their structural design. RF binding shall continue as formwork and shuttering work is progresses.

An appropriate design the quality of the materials used.

The RF shifting and binding shall be started as soon as shuttering is completed. A guide to the correct number and po-. The RF shifting and binding has to be commenced right after shuttering is undertaken. Casting is a manufacturing process by which a molten material such as metal or plastic is introduced into a mold allowed to solidify within the mold and then ejected or broken. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab. The distance the concrete.

Source: qualityengineersguide.com

Source: qualityengineersguide.com

The surfaces of construction joints should the thoroughly wet free from laitance before pouring fresh concrete. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab. The casting procedure is as follows. Rod each layer 25 times with a bullet-tipped 58-inch diameter rod to compact each layer. Work procedure Site planning Delivery fresh concrete shall be batched from the approved supplier of concrete.

Source: civildigital.com

Source: civildigital.com

A guide to the correct number and po-. What is casting process in manufacturing. Purpose and scope The purpose of this method statement is to explain the proper procedure on how to prepare and cast. Center line and lay out including column starter marking. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab.

Source: slideplayer.com

Source: slideplayer.com

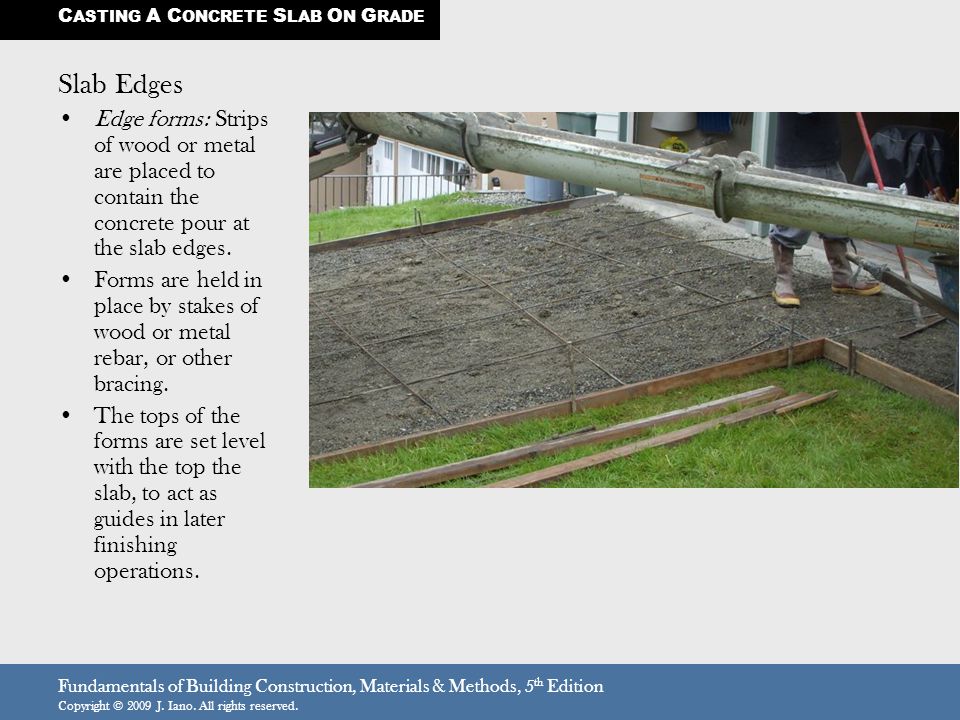

The work procedure of slab casting involves marking the slab placing the reinforcement performing formwork for the slab and finally placing the concrete. In some cases concrete formwork may need to be stripped removed as quickly as 3 days after the placement. Title Method Statement for Casting Slab on Grade 2. Casting is a manufacturing process by which a molten material such as metal or plastic is introduced into a mold allowed to solidify within the mold and then ejected or broken. A guide to the correct number and po-.

Source: nzdl.org

Source: nzdl.org

A guide to the correct number and po-. The reinforcement of slab must be in proper alignment and the slab bends must be lifted up to give a bend up of height 125 mm less than slab thickness without cover. Fi g u r e 10 illus-t r ates the proper insert placement for va r ious situations. Kalpataru Grandeur Saicharan Properties Ltd. A guide to the correct number and po-.

Source: civilarc.com

Source: civilarc.com

Purpose and scope The purpose of this method statement is to explain the proper procedure on how to prepare and cast. Concrete floor slab construction process includes erection of formwork placement of reinforcement pouring compacting and finishing concrete and lastly removal of formwork and curing of concrete slab. An appropriate design the quality of the materials used. After filling and rodding raise the cone to allow the concrete to subside. Lift and brace inserts must be c a r efully positioned in the slab at p r oper distances from edges and openings and must be kept upri g h t d u r ing the casting operation.

Source: structville.com

Source: structville.com

Checking procedure step by step considered after casting of slab Site. If the concrete is prepared at site carefully handle the process of batching water content mixing and testing of fresh concrete. The work procedure of slab casting involves marking the slab placing the reinforcement performing formwork for the slab and finally placing the concrete. Concrete floor slab formation method involves the construction of formwork placing and reinforcement of the floor. Before placing the concrete Check the reinforcement details with bar bending schedule and get an approval from structural consultant.

Source: youtube.com

Source: youtube.com

The first step is to bring together and put up formwork the second step is to put in order and place reinforcement the third step is. Ensure that the beams are primarily cast in layers and compacted properly by vibrators. Fill the mold in three equal layers by volume not by height. Collect samples for maturity testing. An appropriate design the quality of the materials used.

Source: constructioncost.co

Source: constructioncost.co

Ensure that the beams are primarily cast in layers and compacted properly by vibrators. A guide to the correct number and po-. Kalpataru Grandeur Saicharan Properties Ltd. Fi g u r e 10 illus-t r ates the proper insert placement for va r ious situations. Make sure that the cover blocks are at right position and stay okay while concreting.

Source: buildipedia.com

Source: buildipedia.com

Concrete floor slab construction process includes erection of formwork placement of reinforcement pouring compacting and finishing concrete and lastly removal of formwork and curing of concrete slab. Title Method Statement for Casting Slab on Grade 2. Laitance removal and slurry chipping on slab at column top. The surfaces of construction joints should the thoroughly wet free from laitance before pouring fresh concrete. Whether you are casting concrete for foundation footings to support a simple timber structure or for a solid slab that will form the floor of a garden building to be built from wood the principles are exactly the same.

Source: civilblog.org

Source: civilblog.org

Laitance removal and slurry chipping on slab at column top. Work Procedure for RCC Slab Casting. If the concrete is prepared at site carefully handle the process of batching water content mixing and testing of fresh concrete. Laitance removal and slurry chipping on slab at column top. In high rise buildings and skyscrapers thinner pre-cast concrete slabs are slung between the steel frames to form the floors and ceilings on each level.

Source: youtube.com

Source: youtube.com

Laitance removal and slurry chipping on slab at column top. Title Method Statement for Casting Slab on Grade 2. An appropriate design the quality of the materials used. The RF shifting and binding has to be commenced right after shuttering is undertaken. Whether you are casting concrete for foundation footings to support a simple timber structure or for a solid slab that will form the floor of a garden building to be built from wood the principles are exactly the same.

Source: civilsnapshot.com

Source: civilsnapshot.com

Whether you are casting concrete for foundation footings to support a simple timber structure or for a solid slab that will form the floor of a garden building to be built from wood the principles are exactly the same. Form work for the slab. The surfaces of construction joints should the thoroughly wet free from laitance before pouring fresh concrete. The RF shifting and binding has to be commenced right after shuttering is undertaken. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab.

Source: researchgate.net

Source: researchgate.net

It has to be prepared according to the BBS arranged as per the approved drawing. Checking procedure step by step considered after casting of slab Site. In some cases concrete formwork may need to be stripped removed as quickly as 3 days after the placement. Simple residential basement slab to a heavy-duty industrial floor. The quality of a completed floor slab is dependent on.

Source: constructionqueries.wordpress.com

Source: constructionqueries.wordpress.com

Then do the work of preparing slabs and beams to be ready for concrete. The RF shifting and binding shall be started as soon as shuttering is completed. Checking of Alinement right angle plum from below floor. What is casting process in manufacturing. A guide to the correct number and po-.

Source: researchgate.net

Source: researchgate.net

Title Method Statement for Casting Slab on Grade 2. Work Procedure for RCC Slab Casting. Laitance removal and slurry chipping on slab at column top. However no matter how basic or complex the floor is the construction method is similar and includes. The work procedure of slab casting involves marking the slab placing the reinforcement performing formwork for the slab and finally placing the concrete.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title concrete slab casting procedure by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.