Your Back propping concrete slab images are available in this site. Back propping concrete slab are a topic that is being searched for and liked by netizens today. You can Download the Back propping concrete slab files here. Download all royalty-free images.

If you’re searching for back propping concrete slab images information linked to the back propping concrete slab keyword, you have come to the ideal site. Our website frequently gives you suggestions for refferencing the maximum quality video and picture content, please kindly hunt and locate more enlightening video articles and graphics that match your interests.

Back Propping Concrete Slab. Ad More than 30MM homeowners have used HomeAdvisor to find quality professionals. It provides an alternative load path through the superstructure to ensure the existing or as built permanent elements are not overloaded given the imposed load. B_L 300 unitless Number of Back Propping Level required. If it does not then backpropping is required see Design of backpropping on page 3.

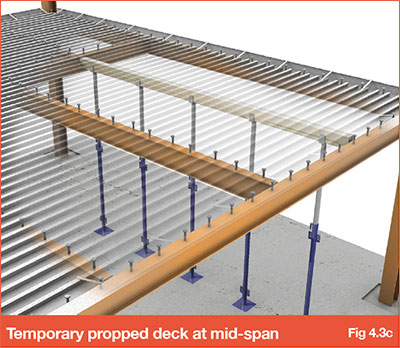

Start the dismantle process from lower floors. Back propping is used to support a suspended slab while the formwork is being stripped. Wedge Anchors - Sleeve Anchors - Concrete Screws - All In Stock - Free Freight. Less than 9 compression. The construction procedure is really important along with the structural design. The self-weight of the completed concrete slabs is generally assumed in backpropping calculations to be based on a density of 24 kNm³ for building multi-storey flat slab structures.

The systems modular nature simplifies the entire process naturally creating a 18m grid.

The conventional approach to the design of backpropping is to assume a uniform distribution of load between supporting slabs. This guide provides new and improved recommendations for striking formwork and gives new procedures for backpropping reinforced in-situ concrete flat slabs less than 350mm thick. This article focuses on the back propping arrangement in flat. The conventional approach to the design of backpropping is to assume a uniform distribution of load between supporting slabs. Once the level is shored formed and cast the concrete is left to cure until the slab has sufficient strength to support itself. Early striking and improved backpropping for efficient flat slab construction.

Source: idh-design.co.uk

Source: idh-design.co.uk

To address this last months article in the series covered the theory and detailed methods recommended for calculating backpropping loads based on research carried out for the European Concrete Building Project ECBP and published by the Building Research. Back Propping back propping can be similar to slab propping. Reduce heat loss by 56. Early striking and improved backpropping for efficient flat slab construction. Construction is a subject often misunderstood in the industry.

Source: idh-design.co.uk

Source: idh-design.co.uk

H 350 m Clear height between slab-slab See Outline Dwg. Backpropping of concrete slabs during construction is a subject often misunderstood in the industry. The conventional approach to the design of backpropping is to assume a uniform distribution of load between supporting slabs. H 350 m Clear height between slab-slab See Outline Dwg. Early striking and improved backpropping for efficient flat slab construction.

Source: builderbill-diy-help.com

Source: builderbill-diy-help.com

It provides an alternative load path through the superstructure to ensure the existing or as built permanent elements are not overloaded given the imposed load. Concrete and rebar included a load of approximately 37500 tons will rest on the 493 seismic pads when work on the B2 slab is completed. The procedure that need to be considered in casting the above slab is shown in the figure below. The structural engineer may require that a newly poured concrete slab should be supported by props for a certain amount of time until it has gained enough strength to support the loads to be imposed upon it. The conventional approach to the design of backpropping is to assume a uniform distribution of load between supporting slabs.

Source: idh-design.co.uk

Source: idh-design.co.uk

Between the levels of supporting slabs. Over 5 Million Submitted Reviews for Pros on HomeAdvisor. It provides an alternative load path through the superstructure to ensure the existing or as built permanent elements are not overloaded given the imposed load. Back propping refers to the addition of propping support to reinforce an existing suspended floor system. The determination of sufficient strength must come from the slabs design engineer and.

Back Propping back propping can be similar to slab propping. Less than 9 compression. Between the levels of supporting slabs. If the supporting slab has sufficient capacity to carry the loads imposed backpropping is notrequired. The number of supporting slabs required is then determined by the spare capacity1 of each of the slabs to support the additional weight of the next slab to be cast.

H 350 m Clear height between slab-slab See Outline Dwg. Propping has begun in the Tokamak Complex Seismic Pit. The systems modular nature simplifies the entire process naturally creating a 18m grid. Heavy Duty Propping The term heavy duty. The structural engineer may require that a newly poured concrete slab should be supported by props for a certain amount of time until it has gained enough strength to support the loads to be imposed upon it.

Source: cassaform.com.au

Source: cassaform.com.au

Back propping of RC and post tensioned concrete floor Back propping of RC and post tensioned concrete floor oranda Civil. B_L 300 unitless Number of Back Propping Level required. Backpropping of concrete slabs during construction is a subject often misunderstood in the industry. The procedure that need to be considered in casting the above slab is shown in the figure below. This article focuses on the back propping arrangement in flat.

Source: shapeheritage.com

Source: shapeheritage.com

Ad Under Concrete or Wood Floors. The number of supporting slabs required is then determined by the spare capacity1 of each of the slabs to support the additional weight of the next slab to be cast. Ensure that the concrete has reached its specified strength. Weight of concrete in new slab plus the self-weight of the temporary works plus construction live load on new slab. Concrete and rebar included a load of approximately 37500 tons will rest on the 493 seismic pads when work on the B2 slab is completed.

Backpropping of concrete slabs during construction is a subject often misunderstood in the industry. The construction procedure is really important along with the structural design. The technique of stripping the formwork in a suspended slab while still keeping it supported. For efficient slab construction incorporating back propping in early striking of the concrete structure can enable the following key outcomes- Allowing the formwork to become available sooner for reuse reducing the quantity of formwork required Gives earlier access for follow on trades and. The systems modular nature simplifies the entire process naturally creating a 18m grid.

Source: idh-design.co.uk

Source: idh-design.co.uk

Start the dismantle process from lower floors. The technique of stripping the formwork in a suspended slab while still keeping it supported. Back propping of RC and post tensioned concrete floor Back propping of RC and post tensioned concrete floor oranda Civil. It provides an alternative load path through the superstructure to ensure the existing or as built permanent elements are not overloaded given the imposed load. Less than 9 compression.

Source: smdltd.co.uk

Source: smdltd.co.uk

Start the dismantle process from lower floors. Back propping is used to support a suspended slab while the formwork is being stripped. Find Local Pros for FREE. Refer to the concrete cube test results. The systems modular nature simplifies the entire process naturally creating a 18m grid.

Source: cassaform.com.au

Source: cassaform.com.au

The construction procedure is really important along with the structural design. 2 For sides of beam formwork shall be removed after 24 hours. CL 360 kNm² Construction Live Load Construction Live Load 360 kNm² Table -2. Construction is a subject often misunderstood in the industry. The procedure that need to be considered in casting the above slab is shown in the figure below.

To address this last months article in the series covered the theory and detailed methods recommended for calculating backpropping loads based on research carried out for the European Concrete Building Project ECBP and published by the Building Research. Ad Buy Concrete Fasteners Direct. To address this last months article in the series covered the theory and detailed methods recommended for calculating backpropping loads based on research carried out for the European Concrete Building Project ECBP and published by the Building Research. Between the levels of supporting slabs. When we look into back propping there are two common applications that may require this technique or.

Source: builderbill-diy-help.com

Source: builderbill-diy-help.com

DL 875 kNm² Weight of Concrete Weight of Concrete 875 kNm² Pre- Calculated. When slab propping is used to support a slab the loads. The procedure that need to be considered in casting the above slab is shown in the figure below. Back Propping back propping can be similar to slab propping. 4Bam soffits props left under7 days 5Removal of props to slabs Spanning upto 45 m-7 days.

Heavy Duty Propping The term heavy duty. Vapor Barrier and Thermal Break. Back propping refers to the addition of propping support to reinforce an existing suspended floor system. Back Propping back propping can be similar to slab propping. Propping Slab Propping slab propping can be used to support a concrete slab during construction or after completion.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title back propping concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.